Editor’s Note: This month, EducationNC starts a year-long series looking at best practices in STEM education, including the nexus with early childhood literacy, to prepare the workforce of the future in 10 counties in Eastern North Carolina: Beaufort, Cumberland, Duplin, Edgecombe, Greene, Johnston, Lenoir, Nash, Pitt, and Wilson.

The craft of teaching requires continuous learning, a rolling professional development that requires adaptation to new trends and reflection on best practices. North Carolina is fortunate to have many formal structures of mentorship for beginning teachers.

But sometimes teachers find themselves in informal partnerships, working together to offer support and ideas. That’s what happened with two teachers in Duplin and Lenoir Counties: One a veteran teacher, the other a beginning teacher, but both working together to learn how best to use their schools’ new STEM labs.

Sarah Neider is a third-year lateral entry teacher at Woodington Middle School in Kinston. As a beginning teacher, Neider is a part of the New Teacher Support Program. In her first two years at Woodington, Neider taught business and basic computing skills, but in the summer between her second and third year, Woodington Principal Patrick Phillippe reached out to her and asked if she wanted to head up the school’s new PITSCO Education STEM lab.

“He said, ‘I want us to get this. And would you be interested in [teaching] it?’ And I said, ‘Absolutely.'” Neider said.

Phillippe felt that given Neider’s background teaching computers, keyboarding, and business applications in her first two years that she would be a good fit for the STEM lab. He was also impressed with the work of his new teacher in her first two years. “She has done a phenomenal job,” Phillippe said.

Neider reached out to her Beginning Teacher mentor at East Carolina University, Denise Hunt, for advice on implementing her new curriculum and lab. Hunt, who also works with beginning teachers in Duplin County, recommended she contact veteran teacher Jennifer Rivenbark at E.E. Smith Middle School in Kenansville. Rivenbark had just launched her own STEM lab only months before.

Though she had been teaching for close to a decade, Rivenbark was still new to the PITSCO curriculum. In that regard, they were both beginners with STEM education and their new labs.

“Ms. Rivenbark was also in the very beginning phases but had a little bit of time under her belt. She was able to guide me and help me in ways that I didn’t get at training, like more hands-on stuff,” Neider said.

Rivenbark was able to share with Neider materials she had already created for her lab. That sharing of resources and ideas gave Neider a head start on planning for her own lab.

But Rivenbark will admit that while she had slightly more experience in the lab than Neider, and had been teaching significantly longer, she, too, was still learning.

“For my first six weeks in here, I thought ‘What have I done?,'” Rivenbark said with a laugh. “It’s such a learning curve when you have taught one subject…and then you come in here and it’s twelve different subjects…it’s going to be quite the learning curve.”

With Phillippe’s full support, Neider used one of her teacher workdays to visit Rivenbark’s lab in Duplin County. Neider spent a morning observing Rivenbark in her classroom and asking questions. Seeing the lab being used in real time by students left a strong impression on Neider.

“I was in love,” Neider said. “I loved it.”

But without having her own lab or having received the training on how to use it, the initial visit left Neider a bit overwhelmed. At the time of her visit, Neider still had not received her curriculum training and did not yet have a lab, but she and Rivenbark continued to communicate, sharing ideas.

“Last summer, I had four-to-five weeks to prepare, to sit down with some of the modules and learn some of the stations,” Rivenbark said. “[Sarah] didn’t have that.”

Yet even though Neider had not had her official training, the two began working, with Rivenbark sharing her initial experiences and what she had learned. Rivenbark suggested she return for another meeting after the two-day PITSCO training.

Principal Phillippe then gave her another day to visit Rivenbark at E.E. Smith. This time, however, she had a full understanding of the potential of the lab and was able to dig deeper into brainstorming with Rivenbark.

“She was able to wrap up everything I had in training, and make it not so overwhelming,” Neider said.

“That’s a win-win for both of us, for everybody involved,” Phillippe said when asked about working with Neider to find the time for professional development with Rivenbark.

“First, for Sarah to be able to go in and look at an experienced teacher and see how she’s transitioning and doing her work…that’s great for [Sarah],” Phillippe said. “And two, they are able to bounce [ideas] back and forth off each other.”

“When [a student] asks you a question, you want to lead them to the answer,” Rivenbark said. “Normally [in a traditional classroom], I am teaching and they are doing. In here, I switch roles from the teacher to the facilitator.”

Rivenbark gives an example of an electronic circuit project at one of the stations in her STEM lab, where a team of students’ light was not working.

“I can look at it…and see that there is a capacitor or resistor not in the right place, and I can spot it but I can’t tell them,” Rivenbark said. Instead, Rivenbark asked students to think critically about the circuitry they had built and try and understand where in the construction process the failure might have happened. “I give them higher-order thinking questions; they have to go back and think about it. They can’t just say, ‘Well, it’s not working.'”

Rivenbark encourages students to trace their steps and see where they may have made a mistake. The result may be a few days wrestling with a single problem, but ultimately the students find their own mistakes.

Neider has noticed a similar change in her pedagogical approach.

“Basically, I am like a facilitator,” Neider said. “They are doing hands-on stuff. They are watching videos, then they go and do the activity, then they have to go back and listen and do the next thing.”

But Neider is not hands-off in her instruction. She goes around to each station, checks in on each group, and quizzes them on their work, making sure they are on task and following the assignments.

“[Before] I was standing up. PowerPoints. Test. Lectures. Everything,” Neider said. “But with this I walk around and help them. It’s really fun.”

She now moves around the class more and interacts with the students more directly. It has also helped with classroom control and has improved student behavior. Each work station in the lab comes with a red call light. When they have a question, instead of yelling or talking over each other, students simply turn on the call light and wait for her to stop by.

“Sometimes it takes you a while to get to them, because so many students may have their lights on,” Neider said. “But sometimes they turn them off cause they figured it out on their own.”

Neider points to a small engine in the classroom, one of the stations in the lab. She proudly notes that her students can now take apart and reassemble the engine. “They take apart the engine and they have to find different things on it,” Neider said. “They open it up, and then I come over and quiz, ask them different things about it.”

In the Woodington lab there is a station for electronics that requires students to solder components together to create a circuit board that can replicate a police siren.

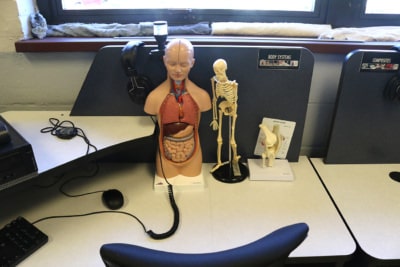

Her lab also includes a CADD station, teaching students to create house designs and plans for building. There are labs where students can create miniature race cars. The microbiology station lets students examine different types of micro-bacteria. There’s an anatomy lab. An applied physics lab. And many others.

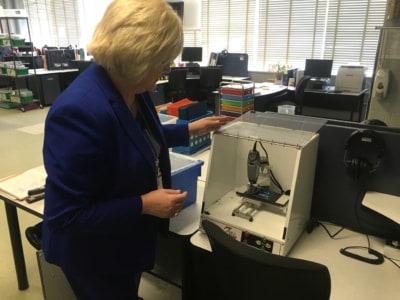

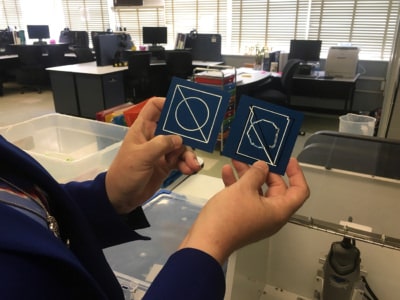

But the most popular station among her students is the CNC Manufacturing lab. CNC stands for “computerized numerical control.” The lab exposes students to the next generation of machining — instead of manually-operated lathes or drill presses, students program software to create designs and products.

“First, they have to do it manually,” Neider said. “They have to manually move the machine.”

Students draw a design by hand, then program the machine to draw the same design. They then compare the two outcomes.

“[The manual design] doesn’t come out perfect, but when they program the machine, it comes out perfect,” Neider said.

There’s also a robotic station, with a robotic arm the students can program to move and pick up objects.

Principal Phillippe describes the environment of the lab as “the best noise you’ve ever heard.”

“It’s not walking in a classroom where you have them yelling at each other,” Phillippe said. “They’re talking, they’re interacting, they’re engaged in what they are doing.”

According to Phillippe, other teachers frequently stop by during their planning periods to see the students’ work and to ask questions about their projects.

When they don’t have questions, students are interacting with the video tutorial or working on their project.

Each station in the lab is a module with seven sessions, including a pre-test and post-test and activities in between.

The stations in the Woodington lab were not chosen at random, but instead were decided upon through conversation with the school district and local industry. Through the PITSCO model, each lab can be tailored to a teacher’s specific curriculum with different stations focusing on a different field of study or career.

“Lenoir County — and also Mr. Phillippe — met and decided that these 14 stations would be geared toward our county and jobs in our county,” Neider said, noting that labs in other counties might have different stations depending upon the industries in their community.

“I met with the Lenoir County Manufacturer’s Association,” Phillippe said. “We wanted to make sure everything we do in our lab lined up with what business and industry needed in our area.”

Having worked as an assistant principal at the high school Woodington feeds into, Phillippe also knew what courses would be available to his students, which factored into which modules were selected for the lab.

“At the high school, they’ve got agriculture, they have carpentry, they’ve got engines, they’ve got CADD,” Phillippe said. “I knew what my kids were going to be moving to.”

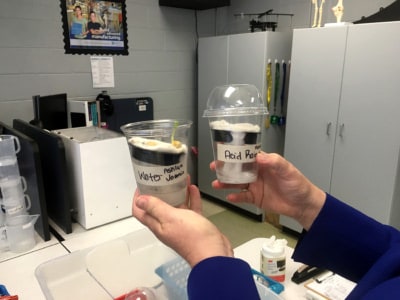

Like in Lenoir, the modules for the Duplin County labs were selected with input from the community. Rivenbark and her colleagues communicated with the local hospital, community college, and local industries to learn about what academic and workforce skills students needed for STEM careers in the area. Each organization and business was given a list of modules and asked to recommend 12. Then the teachers met with the district to synthesize the responses into the final 12 modules for their labs.

But Phillippe sees the hands-on learning of the lab as offering more to students than just exposure to different STEM careers. He sees it as a way to teach important social and workplace skills, especially for his incoming sixth graders who feed into the school from three different elementary schools.

“When they get out into the job force, they may get a job where they have to work hand-in-hand with somebody,” Phillippe said. “And if it’s their first experience with that, it might not be good. This builds teamwork.”

Neider agrees, pointing out that students are randomly sorted by station and with their partners. Neider notes that while sometimes students want to choose their station or partners, she reminds them that in the workplace they may not have a choice about what they are doing on any given day or who their co-worker might be.

Duplin County has several STEM and college readiness initiatives underway throughout the school district. Through the “The Duplin Promise,” the district has launched a system-wide effort to create a college-going culture from pre-K through high school, and James Kenan High School in Duplin County is one of the newest Prepared STEM Schools of Distinction.

And the district has been an early adopter of STEM labs in its middle schools. “It started three years ago with Duplin County Schools working with Golden LEAF and STEM East,” Rivenbark said. “They wanted to put in nine STEM labs. They did it over a three-year period, so each year three schools got STEM labs.”

According to Rivenbark, the nine labs were funded through a $1 million dollar grant from Golden LEAF, roughly $100,000 per lab. Teachers were trained over the summer prior to the launch of their labs.

According to Neider, Woodington Middle School, a 1:1 school where each student has his or her own tablet, was the first school in Lenoir County to have a STEM lab.

STEM East approached Phillippe in the summer of 2015 about creating a lab at the school using a Duke Energy grant. Knowing that he couldn’t get a STEM lab up and running before August and the start of the school year, Phillippe decided to accept the offer but asked for time to get a plan in place.

Throughout the planning process, the school met with PITSCO representatives about such details as layouts and floor plans to optimize the classroom space. It was a productive working relationship. But even after all the details had been settled and everything agreed upon, Phillippe still felt something was missing.

“I had some extra monies around toward the end of the year and said, ‘We need a 3D printer in there,'” Phillippe said. He purchased two additional modules to go along with the printer, which will increase the student capacity in the lab from 28 to 32. He plans to implement the modules starting next year for the school’s eighth graders to use as a reward for the work they have done in the lab in the previous two years.

Phillippe is an advocate for STEM education, having taught science for 10 years at Woodington before moving into administration.

“I just love it,” Phillippe said.

Phillippe is most proud when partnerships in the lab help breakdown stereotypes about who typically enters a STEM field. He cites the time he walked in to find two of the school’s cheerleaders disassembling the lab’s engine. When he asked what they were going to do next, they said, “Well, we’re going to put it back together.”

“You go back in there 30 minutes later, and they’ve taken that thing apart, and whatever section they were working on — carburetor, intake or whatever, manifold — they’ve put it all back together,” Phillippe said with a smile.

Rivenbark tells a similar story about one of her eighth-grade students who changed a leaking faucet in her parents’ home, using skills she had learned in one of her lab modules.

The benefit of the exposure to STEM fields has been evident for students at both schools, with students learning early about potential careers in a science or technology field and providing them with the confidence and knowledge that they can have a valuable career one day.

“It’s really opened their eyes to how much opportunity for the future is out there,” Rivenbark said.

“The students love it,” Rivenbark said later. “You have behavior problems, but in here, they are so engaged. They are so excited about learning, about working with a partner, about building all those 21st-century skills.”

Rivenbark gives the example of one student, a low-level learner who was not doing well in his other classes. One day he called Rivenbark over to his work station. He pointed to his screen: “Look, Ms. Rivenbark.” The student had received a perfect score on his Research, Challenge, and Application (RCA’s) questions.

Rivenbark notes that the new lab has sparked a sense of ownership among her students.

“If you walk around and look [at the lab], the tables are clean, everything is where it’s suppose to be,” Rivenbark said. “And the kids do this because they care about it.”